You may also like

Customer-specific solutions

For more than 75 years, Schwanog has been developing and manufacturing special insert tools that have taken a leading position in the market. In order...

DETAILS

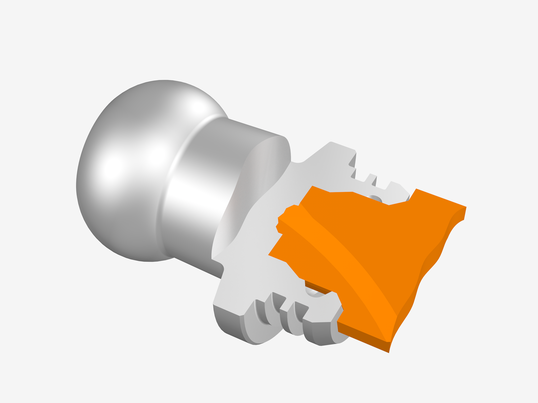

DCI Swiss-type grooving system

Overview of the technical facts: Used on CNC machines and swiss-type automatic lathes Holders from 8 x 8 to 25 x 25 shafts Left and...

DETAILS

Form drilling

Form drilling is one of the most frequent operations found in the machining of precision parts. Schwanog form drill with exchangeable inserts is recommended wherever...

DETAILS

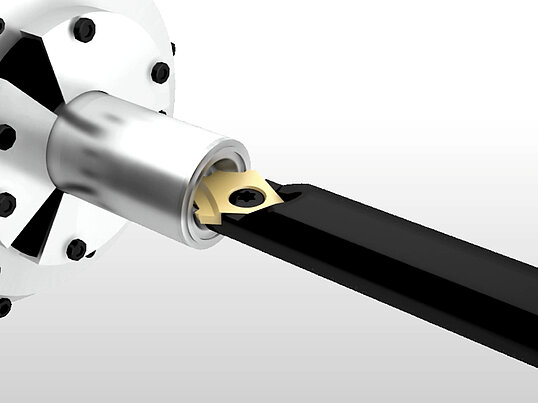

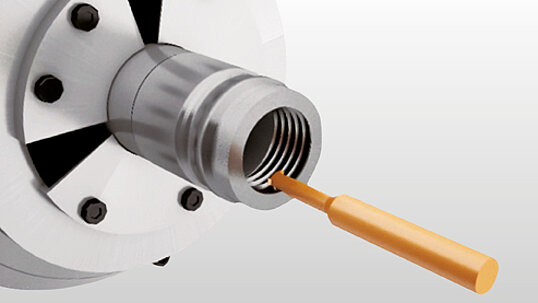

Form drilling with insertable tools

Overview of the technical facts: Two systems with exchangeable inserts of different widths Use on lathes and milling/drilling centers Exchange accuracy < 0.02 mm Also...

Buy product

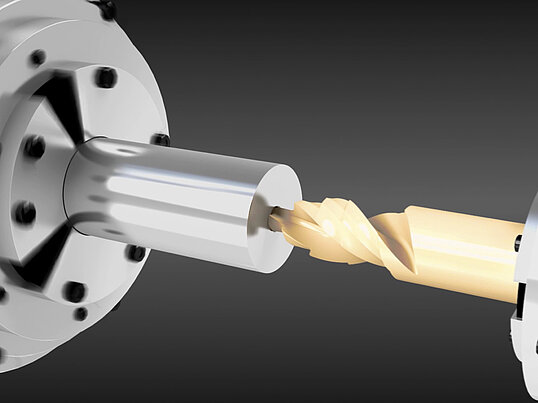

Form drilling with solid carbide drill

Overview of the technical facts: For high-precision drilling For deep drilling When a helical flute is absolutely necessary in order to remove chips In flat...

DETAILS

ID Broaching

Overview of the technical facts: Complete production on one machine No further operation required on an additional machine Production possible up to the collar Can...

details

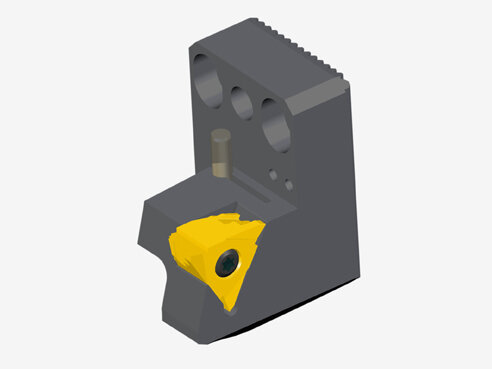

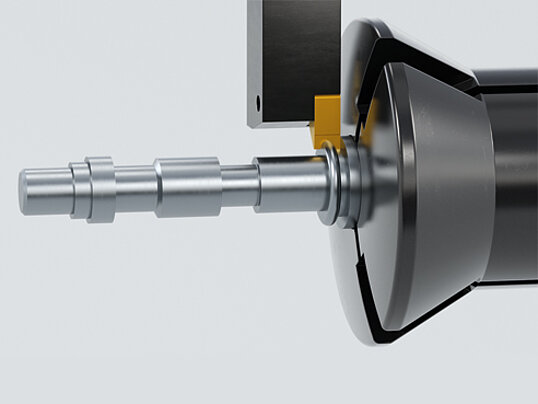

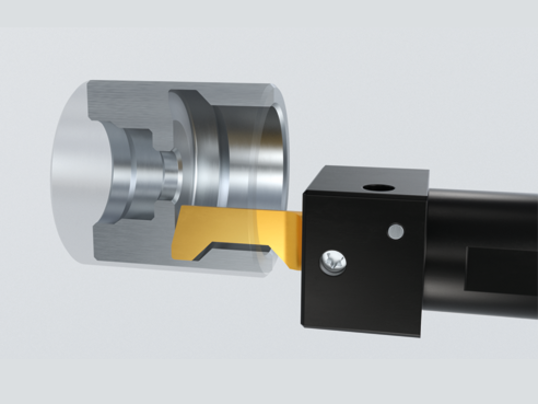

ID Grooving and turning

Overview of the technical facts: Exchangeable insert systems for all machine types Reduction of downtime due to quick changeability For inside diameters > 2 mm...

DETAILS

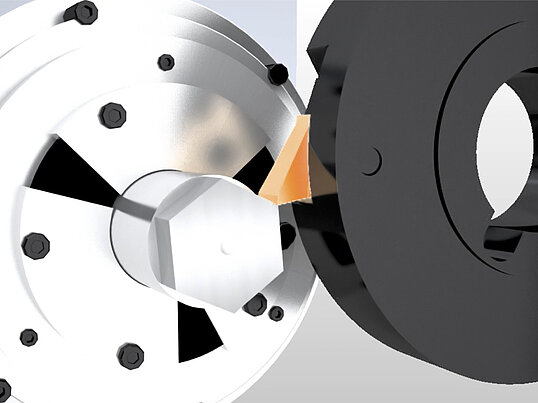

ID Whirling

Overview of technical facts: Solid carbide whirling tools for all common round shaft holders Depending on thread size, 1- to 4-tooth tool Significantly increased tool...

DETAILS

Longitudinal turning

Overview of technical facts: Production of keyway surfaces or polygon in one operation directly on the machine Exchangeable insert system partially with adjustable cutting edges...

DETAILS

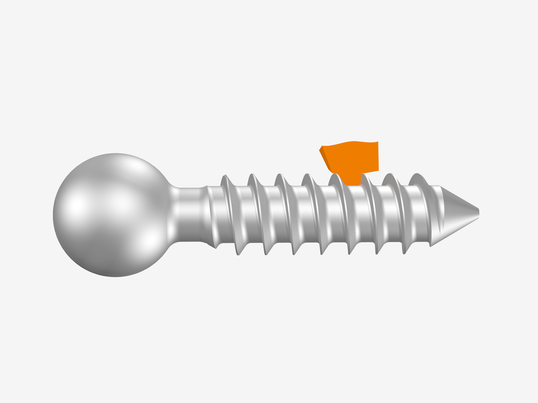

Machining of threads

There are a variety of thread machining processes suitable for different components, thread profiles and thread pitches. Each process offers individual advantages for specific working...

DETAILS

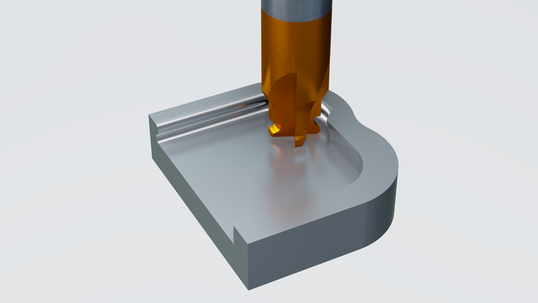

Milling of grooves

Overview of the technical facts: Complete machining directly on the machine Elimination of separate post-machining Fast and process-reliable machining Significant increase in tool life through...

DETAILS

Milling of serrations

Overview of the technical facts: Complete machining directly on the machine No need for separate finishing Fast and process-reliable machining Significant increase in tool life...

DETAILS

Product Categories

Copyright © 2022 Elif Trading. All rights reserved.

Powered by AvangardIT.