Phasep

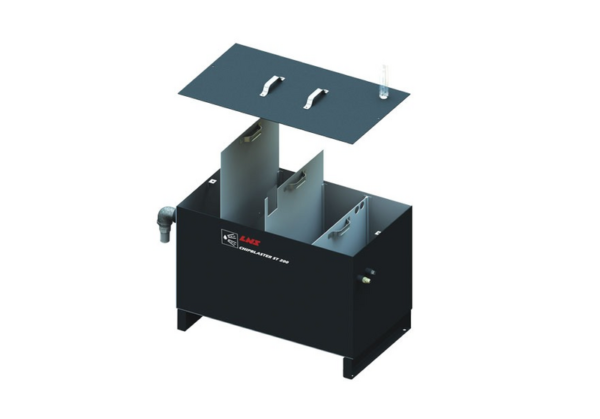

Category: COOLANT MANAGEMENT

Removing waste oil from machine coolant creates a healthier work environment, reduces absenteeism and health issues, and reduces coolant costs. PhaSep uses a unique floating pick-up that skims the tramp oil and coolant mix from the top of the machine sump. As the liquid moves slowly through the patented steel coalescing plates, oil droplets as small as 20 microns are separated from the coolant and rise to the top of the PhaSep unit. When the oil layer builds up sufficiently in the unit, it passes over a specially-designed weir, and is trapped away from the clean coolant. The oil can then be removed periodically through the waste oil drain. Coolant, cleaned of 99% of contaminated oil, is returned directly to the machine sump.

Be the first to review “Phasep” Cancel reply

Related products

Copyright © 2022 Elif Trading. All rights reserved.

Powered by AvangardIT.

Reviews

There are no reviews yet.