You may also like

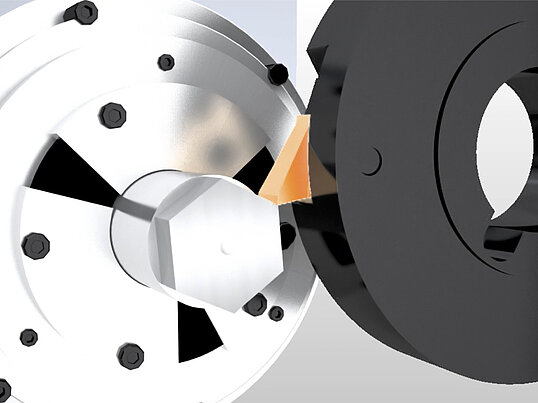

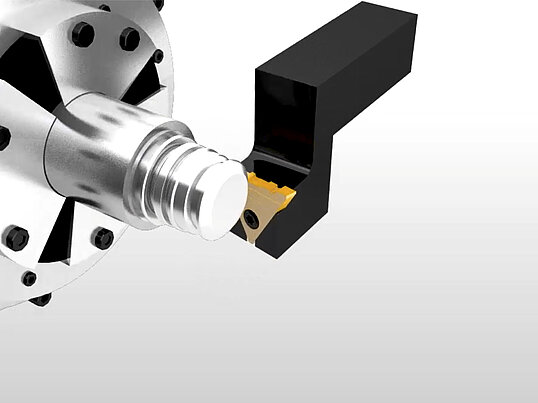

Plunge cutting

Overview of the technical facts: Production of keyway surfaces or polygon profiles in one operation directly on the machine Exchangeable insert system with adjustable cutting...

DETAILS

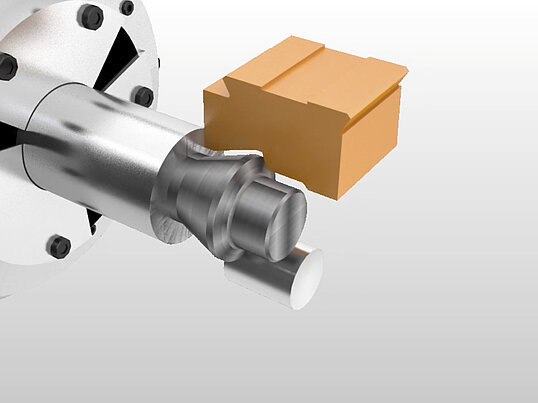

Power Skiving Unit for CNC Turning Centers

A new dimension of high productive gear machining: Skiving of ID and OD gears and splines on CNC Turning Centers with the innovative Power Skiving...

DETAILS

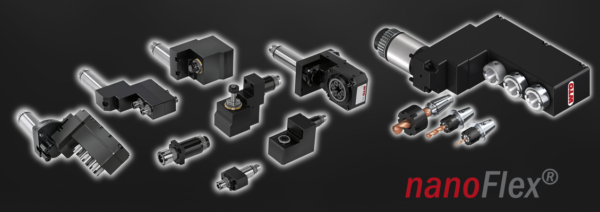

Precision Toolholders for Multiple Spindle Turning Centers

Modular and monoblock precision toolholders for higher productivity. Individually designed for each multiple spindle turning center.

DETAILS

Precision Toolholders for Swiss Type Turning Centers

WTO offers for Swiss Type Turning Centers a suitable comprehensive program of driven precision toolholders. Besides the standard versions for axial and radial operations we...

Read more

QuickFlex® Quick Change System

The perfect combination: ER collet chuck and quick change system in one toolholder. A change system which offers unique advantages: Minimal investment by simply...

DETAILS

QuickFlex® smart

The new generation of Smart Driven Toolholders with intelligent online process monitoring for high process reliability in automated manufacturing cells. All monitoring data will be...

DETAILS

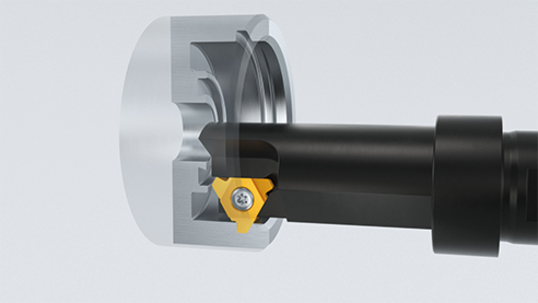

Radial and axial internal grooving

Overview of the technical facts: Exchangeable insert systems for all machine types Reduction of downtime due to quick changeability Significant increase in tool life due...

DETAILS

Revolutionary patented spindle technology for rotation speed up to 75,000 rpm

CoolSpeed® mini is a new, high speed, turbine-driven spindle. It costs a fraction of competing spindle systems. Continuous high precision – The cutting tool shank...

DETAILS

Selector system

Overview of the technical facts: The production batches are divided into small units with selector bins The bin system consists of bins and indexing plates...

DETAILS

Shave tools

Overview of the technical facts: Especially for use on multi-spindle automatic lathes Significantly tighter manufacturing tolerances Highest surface finish quality Process stabilization by counter roller...

DETAILS

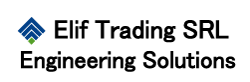

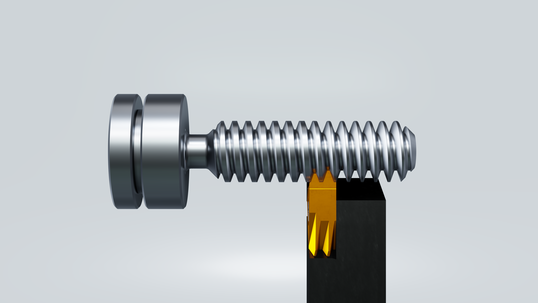

Single-point turning of OD threads

Overview of technical facts: Chasing of single and multi-start standard and special threads Workpiece-specific design of the chaser with roughing and finishing teeth on one...

DETAILS

Product Categories

Copyright © 2022 Elif Trading. All rights reserved.

Powered by AvangardIT.